In part two of our Small Business Week series, learn how one business is using 3D printing to reduce the cost of prototypes.

Today we're going to discuss the dimensions businesses are using to get ahead—specifically, three dimensions.

According to a 2017 prediction from Gartner, "By 2021, 20% of the world's top 100 consumer goods companies will use 3D printing to create custom products."

That means 3D printing will become a factor in one out of five purchases in just a few years.

Today, we're going to talk about 3D-printing adoption and how one small business is improving its prototyping with this emerging tech.

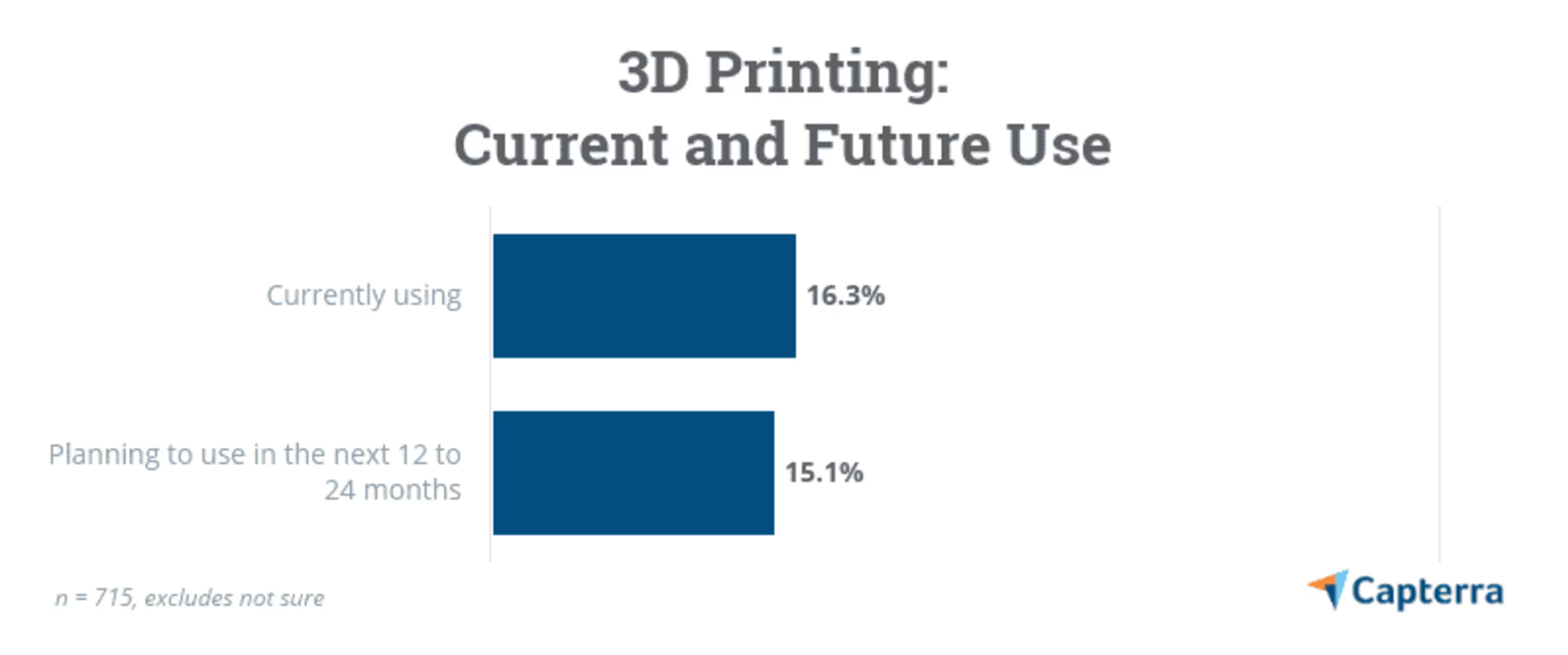

Sixteen percent of small- and midsize-business owners who responded to a Capterra survey on top technology trends are already using 3D printing, and 15% say they are going to use it within the next two years. This corroborates Gartner's prediction that more businesses are going to start using 3D printing in the future.

Many businesses are skeptical of 3D printing. Those without a manufacturing or construction product often think 3D printing isn't valuable for them. However, if you think outside the box, you can come up with some time- and money-saving processes by using a 3D printer to test new designs.

3D printing prototype use in real life

Critter Guard's John Sims offers some insight into the innovators dilemma:

"Bringing a new product (or even a change to an existing product) to the market is a financially risky proposition. It's kind of a 'catch 22' problem—customers don't want to commit without seeing demonstrable proof that the product will serve their purpose, and you (the supplier) need a commitment to justify the R&D dollars required for a traditional development."

Traditional development is a long and tedious process, especially for businesses trying to innovate ahead of competitors. It also requires a lot of initial investment without the promise of returns.

“For manufactured parts, the only way to get your cost/part down to profitable levels is to commit to high volumes. But you don't have market acceptance yet. That's why it's so risky and scary," Sims says.

By using a 3D printer, Sims is able to conceptualize an idea, work with the customer on customization, and test his prototypes before he commits to producing large quantities.

"This process happened in a week or so, rather than perhaps six months or more of the traditional route. And my cost was minimal and certainly justified to get the test in place," Sims explains.

Should you use 3D printing?

I would be lying if I said I didn't fall victim to “shiny ball" syndrome when 3D printers became more affordable. I had an idea to print tags for crafts I sell on Etsy, but little did I know it takes a billion hours to get one tag printed.

OK, it was really more like five hours, but luckily I didn't sink a lot of money into that idea.

3D printers aren't a speedy solution for mass production yet. They are a solution for small-scale production. If you need only one copy of an item, a 3D printer is more worth your while than if you need many copies of an item.

To determine if 3D printing is right for your business, answer these questions:

Do you have a product that can be modified that would require several iterations for testing?

Is your product a physical product that requires customer approval before mass production?

Do you have the ability to design something from scratch or employ the services of a 3D-printing design expert to actualize your ideas?

If your answer is "yes," then you should invest in a 3D printer. There's no need to run out and buy a full-scale 3D-printing workshop though. Depending on the size of the project, you can buy a decent 3D printer to print a small prototype starting at around $100.

Want to know more about 3D-printing technology?

This is a technology that has a vast and diverse number of applications, from printing houses to human organs. Tell us in the comments below how you use 3D printing at your small business.